Product Description

SWECOLP POWER is emerging firm in sugar industry and committed to provide design engineering, inspection, supply and exporting sugar plant equipments to customers in India and overseas countries

Looking to strong business growth in market, we are committed to serve our customer with best quality, design, manufacturing, inspection and performance techniques in collaboration with other partner companies in following areas.

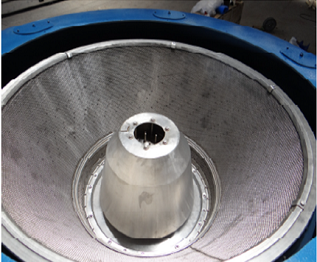

CENTRIFUGALS

- Continuous Centrifugal Machines – SMK1100, SMK1503

- Flat Bottom Fully Automatic Batch Type Centrifugal Machine – SMG500, SMG750, SMG1250, SMG1500, SMC1760, SMC2020

The most significant changes in the process of sugar centrifuging has been the gradual development and increasingly rapid adaptation of continuous machines most of the sugar technologists and sugar manufacturer preferred the continuous centrifugal machines because of its versatility in processing any kind of Massecuite more ever, the operating cost of continuous machine is much less compared to the Batch type centrifugal machine. The continuous machine also helps in reducing power consumption.

MILL HOUSE EQUIPMENTS

- Mill Head Stocks

- Mill Crown Pinions

- Tail bar Couplings

- Trash Plates

- Scrapper Plates

- TRPF & GRPF Head stocks

Machine control system

The Centrifugal machine is provided with special electrical and pneumatic controls to ensure smooth operation of the machine. All the movements of the parts are controlled by pneumatic valves located in the control units. The operations of the machine can be checked and adjusted as per requirements easily. All the cycles of operations can be controlled automatically with over riding manual controls in case of emergencies. All the control timing and settings are adjustable meeting the Massecuite requirements.

Principle of Centrifugal

The continuous centrifugal machine works on single thin layer principle. The Massecuite is feed in the basket, distributed all over and travels in the basket from bottom to top forming helical path since the layer of the Massecuite is very thin any kind of viscous Massecuite can be cured in the centrifuge. Components of the forces parallel to the screen surface and perpendicular to the screen surface operate when the centrifugal force is resolved. The force perpendicular to the screen helps in purging the molasses whereas the force parallel to the screen helps in pushing the sugar particles in upward direction. The frictional force is opposite to this force. The net force brings the sugar particles to upward edge of the basket. At the upper edge the frictional force is zero and there is only centrifugal force by which the sugar particles are thrown into the sugar compartment.